"Polyplastic" has all the necessary technical features to manufacture 4-loops FIBCs (big-bags) of demanded modification in strict accordance with technological specification of the customer. To response logistic needs we produce FIBCs of demanded geometric dimensions. On the request we can also manufacture a rectangular-shaped FIBC.

Most of FIBCs are made with 7:1 Safety Factor thereby exceeding requirements of international and national standards for transportation of dangerous (6:1 Safety Factor) and common bulk cargoes (5:1 Safety Factor).

The loading capacity of 4-loops FIBC varies from 500 to 2000 kg, stacking capacity allowed is up to 8-9 rows.

All FIBC's elements are UV-protected.

With a view to ensuring FIBC's core stability we are manufacturing FIBCs with ratio of height to width/diameter not more than 2:1, otherwise container will be not stable.

The following FIBCs manufactured by "Polyplastic" relate to 13H1 -13H4 UN certified Bulk Bag categories.

FIBCs are tested and certified by LABORDATA (Germany) and Certification Center "Kompozit-Test" (Russia) and meet the requirements of Technical Regulation of the Customs Union ТR CU 005/2011 и ISO 21898:2004(Е) par.5.3.1 (App. В) and par.5.3.2 (App. С).

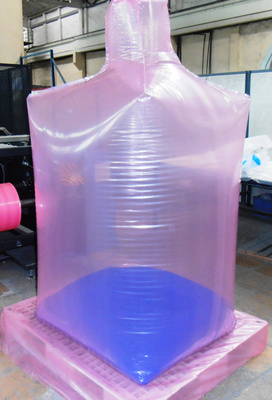

4-loops FIBCs can be completed with formed and heat-resistant polyethylene liners.

Formed liners simplify FIBC preparation for use, allow to reduce the time operator is in contact with loading product and inner surface of the liner while loading/unloading works. Of high importance it is in cases when the loading productis poisonous or unhygienic. For bulk cargoes with high hygienic demands it is possible to produce liners with initially sealed mouths. Formed liners allow to improve loading/unloading capacity up to 2 times making operator's work easier. Internal space of FIBC with a formed liner is more spacious to compare with FIBCs with an usual PE liner. It can be fixed on FIBCs ribs in order not to fall down while unloading works.